The Davos Divide and the New Risk Landscape

The 2026 World Economic Forum in Davos will be remembered not for its solutions, but for its stark exposures. The confrontation between European leaders and the American administration laid bare a deep fracture in the Western alliance, moving geopolitical tensions from the background to the forefront of executive decision-making. President Trump’s antagonistic speech, which included grievances against European allies, questioning of NATO commitments, and a relentless focus on acquiring Greenland, signalled a profound shift toward a world where confrontation is replacing collaboration.

For business leaders, this is not merely political theatre. It is a direct and material risk. The WEF’s own Global Risks Report 2026 identifies “geoeconomic confrontation” as the top risk most likely to trigger a global crisis this year, followed by state-based armed conflict. This environment demands a new playbook for risk management—one that is proactive, integrated, and resilient. The old model of globalisation, with its deeply integrated supply chains and stable multilateral rules, is under severe pressure. As one analysis notes, companies are now forced to consider parallel supply chains and navigate a world where data, trade, and investment are increasingly weaponised.

This post provides a clear-eyed analysis of the key business risks emerging from Davos and outlines six practical, immediate steps to turn this uncertainty into a strategic advantage.

Key Risk Exposures for Businesses After Davos 2026

The events at Davos crystallised several interconnected risk categories that threaten business operations, strategy, and financial performance.

1. Accelerated Geoeconomic Fragmentation & Supply Chain Rupture

The core takeaway is the active unravelling of decades of economic integration. The U.S. administration’s focus on unilateral deals and transactional relationships, as seen with the “framework” for Greenland, undermines the predictable, rules-based system. For businesses, this translates directly into severe supply chain vulnerability. As noted in research from Wharton, companies are being forced to build duplicate, resilient supply chains—a China-centric one and a non-China-centric one—which creates enormous cost and redundancy. This fragmentation is no longer a future threat; it is a present-day operational and financial challenge.

2. Policy Volatility and Regulatory Divergence

Davos highlighted a growing chasm in core policy areas, especially climate and energy. While European leaders and CEOs like Allianz’s Oliver Bäte passionately defended the green transition, calling backlash “bulls—,” the U.S. administration championed fossil fuels and mocked renewable energy policies. This divergence creates a nightmare of regulatory compliance. Companies operating transatlantically face conflicting mandates, as seen historically with EU laws forcing tech changes (like the USB-C port mandate) and strict data rules like GDPR. The risk is being caught in a regulatory crossfire, incurring massive costs to comply with opposing standards in different markets.

3. The Weaponisation of Data and Digital Platforms

A novel and under appreciated risk highlighted in broader analyses is the politicisation of data. Governments increasingly demand control over data of multinational companies within their borders, using it as a tool for political leverage. This was evident in past pressures on tech companies during geopolitical tensions. In a world of “multipolarity without multilateralism,” your customer data, operational data, and intellectual property are no longer just corporate assets—they are geopolitical pawns. This creates immense risks for data security, privacy compliance, and brand reputation.

4. Erosion of the Social License to Operate

Businesses are increasingly “stuck in the middle” of societal and political polarisation. The “streets versus elites” narrative is rising, and companies face pressure to take stands on divisive issues while also demonstrating fealty to national governments. The WEF report identifies misinformation and disinformation as the #2 global risk over the next two years, which can rapidly inflame public sentiment against a brand. Navigating these waters without a clear strategy exposes companies to boycotts, talent attrition, and lasting reputational damage.

Six Practical Risk Management Steps for Business Leaders

In this age of competition, a reactive, wait-and-watch approach is a direct threat to survival. Here is your six-step action plan to build resilience and discover opportunity.

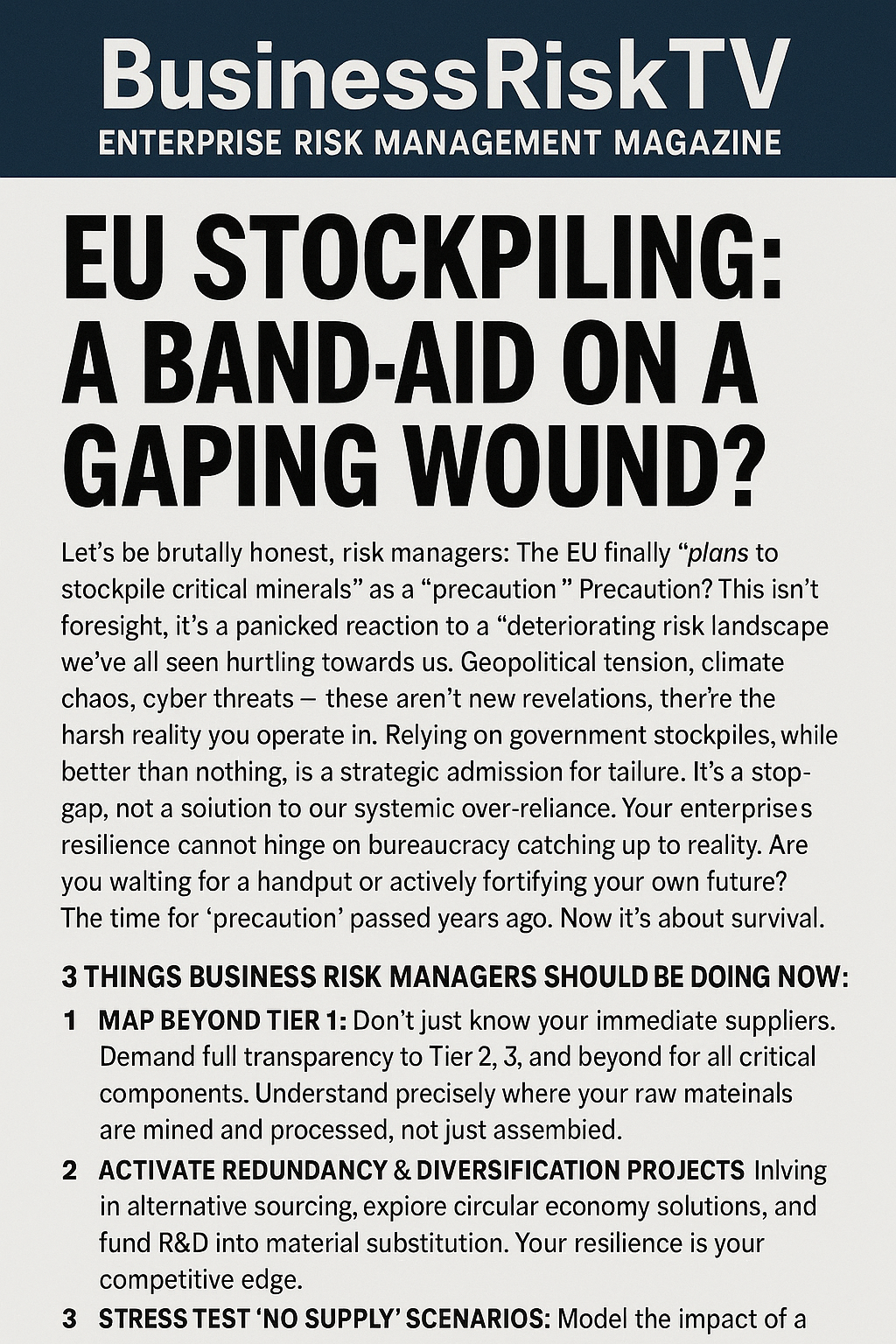

Step 1: Conduct a Geopolitical Stress Test on Your Core Operations

Immediately move beyond traditional SWOT analysis. Launch a cross-functional task force to conduct a dedicated geopolitical stress test. This involves mapping your entire value chain—from critical material sourcing and Tier-N suppliers to key logistics corridors and primary sales markets—against a map of escalating geopolitical flashpoints. Quantify the impact of potential disruptions. For example, what is the financial exposure if a specific trade corridor is tariffed or closed? What alternative suppliers exist outside of geopolitical hotspots? The goal is to move from qualitative worry to quantitative preparedness.

Step 2: Build a Dynamic Early Warning System

You cannot manage what you do not see. Relying on quarterly risk reports is obsolete. Implement an AI-powered early warning system that monitors real-time signals. This system should track not just news, but proposed legislation, social media sentiment, and trade policy adjustments in all your operational regions. Use technology to set alerts for specific keywords related to your industry, as some firms track terms like “oil drilling” in legislative texts. This transforms scattered data into actionable intelligence, giving you a crucial time advantage to respond.

Step 3: Formalise a “Political Risk War Room” and Governance

Political risk can no longer be siloed in government affairs. Follow the advice of experts and establish a cross-functional geostrategic committee that reports directly to the C-suite and board. This committee should include leaders from supply chain, finance, legal, communications, and strategy. Its mandate is to meet regularly, review early-warning intelligence, assess potential financial impacts, and authorise pre-planned contingency actions. This governance structure ensures rapid, coordinated decision-making when a crisis emerges.

Step 4: Develop “Plug-and-Play” Contingency Plans for Key Scenarios

For your top three geopolitical risk scenarios (e.g., “Sudden Tariffs on Key Import,” “Embargo on Technology Exports to Market X,” “Forced Local Data Storage Mandate”), develop pre-approved contingency playbooks. These should outline clear trigger points, decision authorities, and specific actions. For instance, a playbook for new tariffs might include immediate steps to activate alternative shipping routes, pre-negotiated contracts with alternative suppliers, and a communications template for customers. This shifts the response from panic to execution.

Step 5: Diversify Stakeholder Capital and Government Relationships

In a fragmented world, relationships are a critical risk mitigation asset. Proactively diversify your stakeholder engagement beyond traditional channels. Build relationships with policymakers, regulators, and community leaders in all your key markets before a crisis hits. Furthermore, explore financial resilience tools like political risk insurance to protect physical assets and investments in unstable regions. Also, reassess your capital structure and banking relationships to ensure you have access to liquidity from diverse sources if financial markets seize up due to geopolitical shock.

Step 6: Embed Strategic Agility into Your Business Model

Ultimately, the greatest risk is the status quo. Use this moment of clarity to build inherent agility into your business model. This includes:

- Product Design: Develop products with modular designs that can be easily adapted to different regulatory or standards environments (e.g., different power specs, data protocols).

- Manufacturing: Invest in flexible, smaller-scale production facilities (like “micro-factories”) that can be relocated or repurposed faster than monolithic plants.

- Talent Strategy: Cultivate a distributed leadership bench with deep regional expertise, empowering local teams to make rapid decisions in response to local disruptions.

Conclusion: From Risk to Resilient Growth

The message from Davos 2026 is unambiguous: the business environment has fundamentally shifted. The greatest danger now is inaction—the risk of assuming the old rules still apply. However, within this volatility lies significant opportunity. Companies that proactively manage these geopolitical risks will not only protect their existing value but will gain a powerful competitive edge. They will be the ones able to seize market share as slower competitors falter, negotiate from a position of strength with governments, and attract investment as havens of stability.

The time for vague concern is over. The time for deliberate, structured action is now. Begin your geopolitical stress test this week.

—

Protect and grow your business faster with BusinessRiskTV

Subscribe for free business risk management ideas risk reviews and cost reduction tips

Connect with us for free business risk management tips

Read more free business risk management articles and view videos for free

Connect with us for free alerts to new business risk management articles and videos

Navigating Geopolitical Storms: Business Risk Analysis Post-Davos 2026